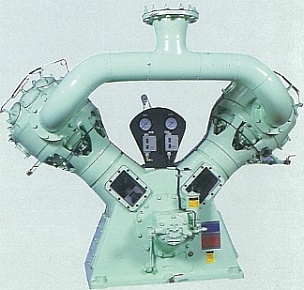

J-Series Piston Compressor

J-Series Piston Compressor

SEAH INDUSRTRY

SEAH INDUSTRY has been producing and providing J-series compressor for last 40 years.

Being well recognized worldwide for its durability and reliability, J-series reciprocating compressor is

specially designed to endure a heavy duty under the 24 hour continuous operation.

They are 100% oil free and their performance and quality are guaranteed until the end of their service life

In addition, they are two-stage model and water cooling type.

|

|

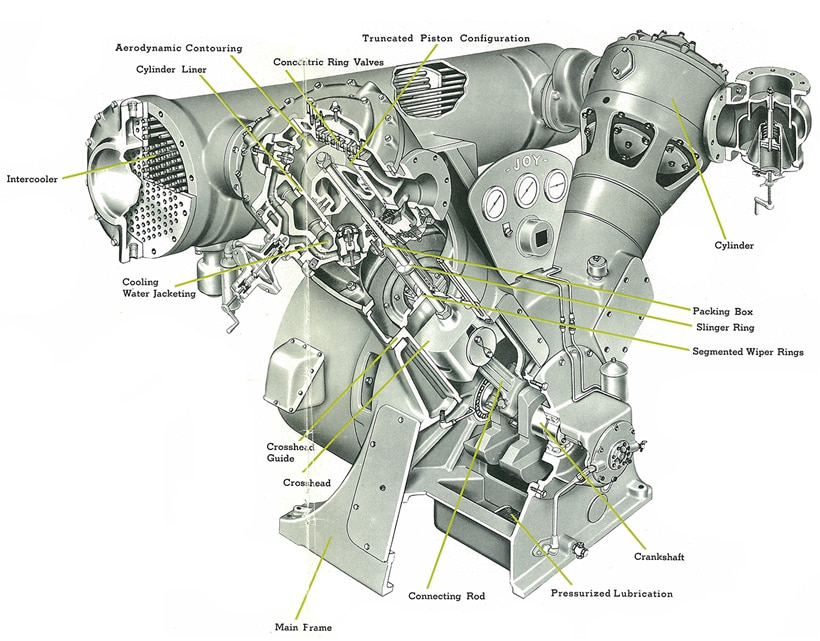

1. Aerodynamic appearance maximized cooling capacity 3. Conical piston with the equal distribution of the pressure he maximized effiency 4. Divided packing ring with a self-care function of the delively surface changeable at field 7. Divided piston ring with 12 times longer life and high efficency maintaining possessing more than two types of SeAH made compressors with the standardization and the interchangeability of all parts of the compressor which ensure 100% oil free for their whole life 9. All kinds of our spare parts produced by JOY-design can be utilized everywhere in the world. | |

Only SEAH INDUSTRY can guarantee the quality of the compressors produced under the 140years JOY design despite lots of imitation of domestic and overseas companies.

| |

Piston rod

to be used for aircarft and piston is designed as conical type to be fitted for the shape of its cylinder head. |

|

Gapless ring

Self-centering gapless compression ring of JOY designed for keeping the nominal size constant irrespective of abrasion operates under the perfectly closed position by removing any gap between cylinder liner and ring which is pointed out as a demerit of traditional fing. 12 times longer life than other products shall be guaranteed. |

|

Cylinder Liner

Cylinder and cylinder head made by specialcasting and cylinder liner special centrifugal casting are easy to disassemble, repair and replace. Water jacket inside of cylinder is designed for the maximum cooling efficiency. And as oil free liner is coated with chrome to avoid any corrosion and extend its life, no corrosion in downtime is allowed.

|

|

-003_00001.jpg)

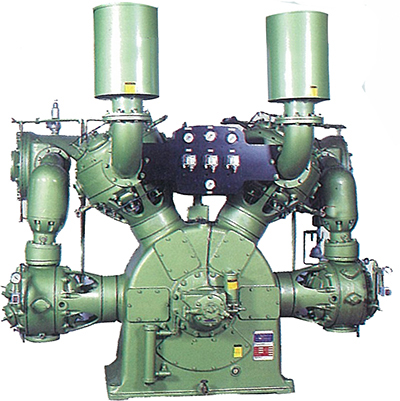

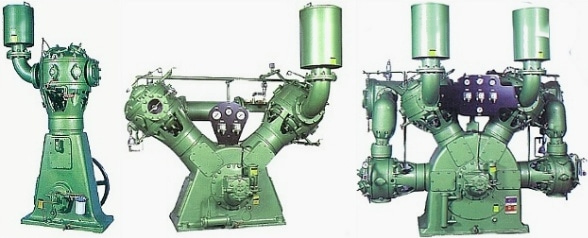

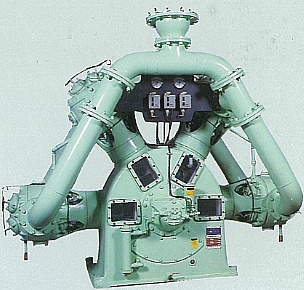

One cylinder

Two cylinder

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Four cylinder

Model

|

J 300 DN

|

J 300 DH

|

J 350 DN

|

J 350 DH

|

J 400 DN

|

J 450 DN

|

J 500 DH

| |

Motor Power |

Hp |

300 |

300 |

350 |

350 |

400 |

450 |

500 |

kw |

225 |

225 |

260 |

260 |

300 |

335 |

370 | |

Working pressure |

kg/cm2.g |

7.0 |

8.8 |

7.0 |

8.8 |

7.0 |

7.0 |

8.8 |

Piston displacement |

m3/min |

44.1 |

44.1 |

53.8 |

53.8 |

68.1 |

68.1 |

68.1 |

Free air delivery |

m3/min |

37.3 |

37.0 |

46.9 |

44.1 |

60.8 |

60.8 |

58.2 |

Cylinder size(1st) |

inch |

14- 1/2 |

14- 1/2 |

16 |

16 |

18 |

18 |

18 |

Cylinder size(2nd) |

inch |

9- 1/4 |

9- 1/4 |

10 |

10 |

10- 1/2 |

10- 1/2 |

10- 1/2 |

Stroke |

inch |

7 |

7 |

7 |

7 |

7 |

7 |

7 |

Revolution |

r.p.m |

585 |

585 |

585 |

585 |

585 |

585 |

585 |

Driving method |

Coupling |

Coupling |

Coupling |

Coupling |

Coupling |

Coupling |

Coupling | |

Starting method |

Reactor |

Reactor |

Reactor |

Reactor |

Reactor |

Reactor |

Reactor | |

Connection pipe diameter(in) |

inch |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

Connection pipe diameter(out) |

inch |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

Cooling water requirement |

L/min |

359 |

359 |

359 |

359 |

667.8 |

667.8 |

667.8 |

Out-line dimension ( mm ) |

Length |

2,260 |

2,260 |

2,260 |

2,260 |

2,590 |

2,590 |

2,590 |

width |

3,100 |

3,100 |

3,100 |

3,100 |

3,100 |

3,100 |

3,100 | |

Height |

2,900 |

2,900 |

2,900 |

2,900 |

2,900 |

2,900 |

2,900 | |

Approx. weight |

kg |

7,600 |

7,600 |

8,000 |

8,000 |

8,500 |

8,500 |

8,500 |

※ Cooling sysm is water cooled type.

※ SEAH INDUSTRY has been producing and in case of more than pressure 10 kg/cm2,

please be sure to develop it after checking with business or technical dept. when ordering.

※ Be careful that above specification can be changeable at any time without any prior notice in order to to upgrade

the quality and performance of the products.

Internal components

Low pressure type

-1.jpg)

-2.jpg)

-3.jpg)