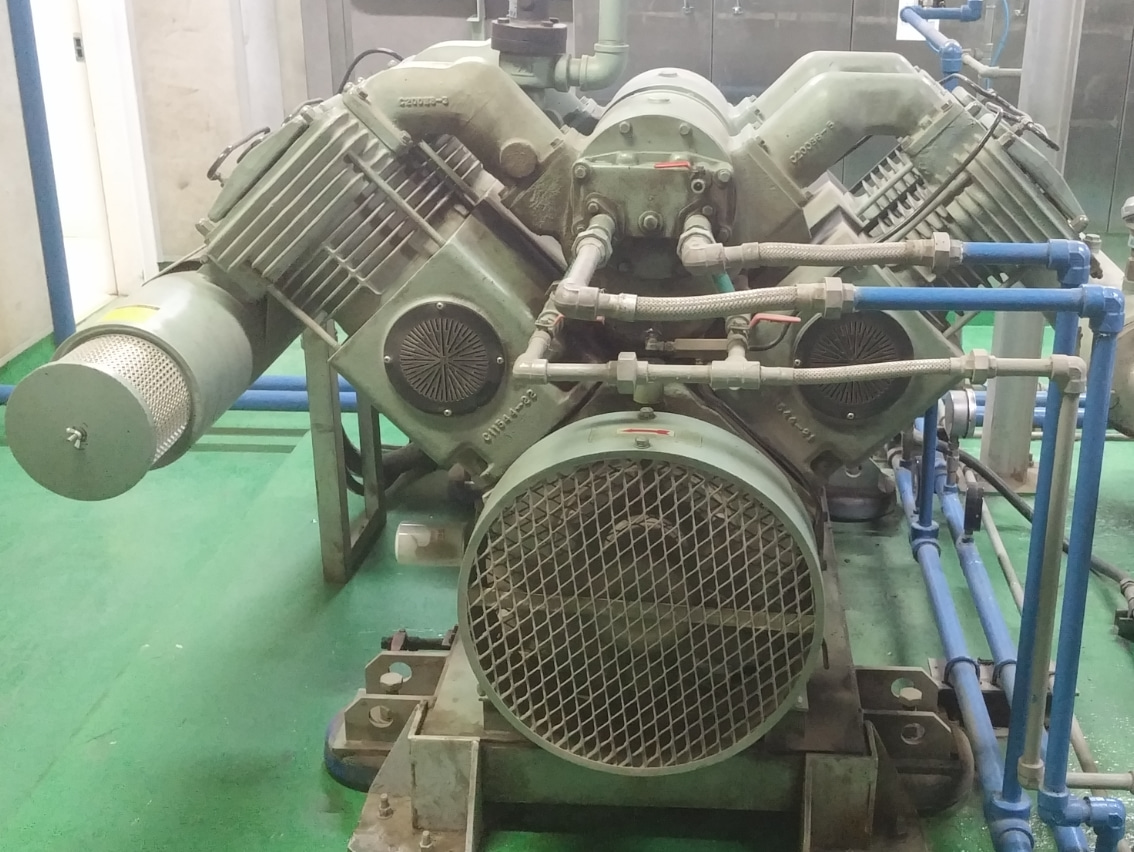

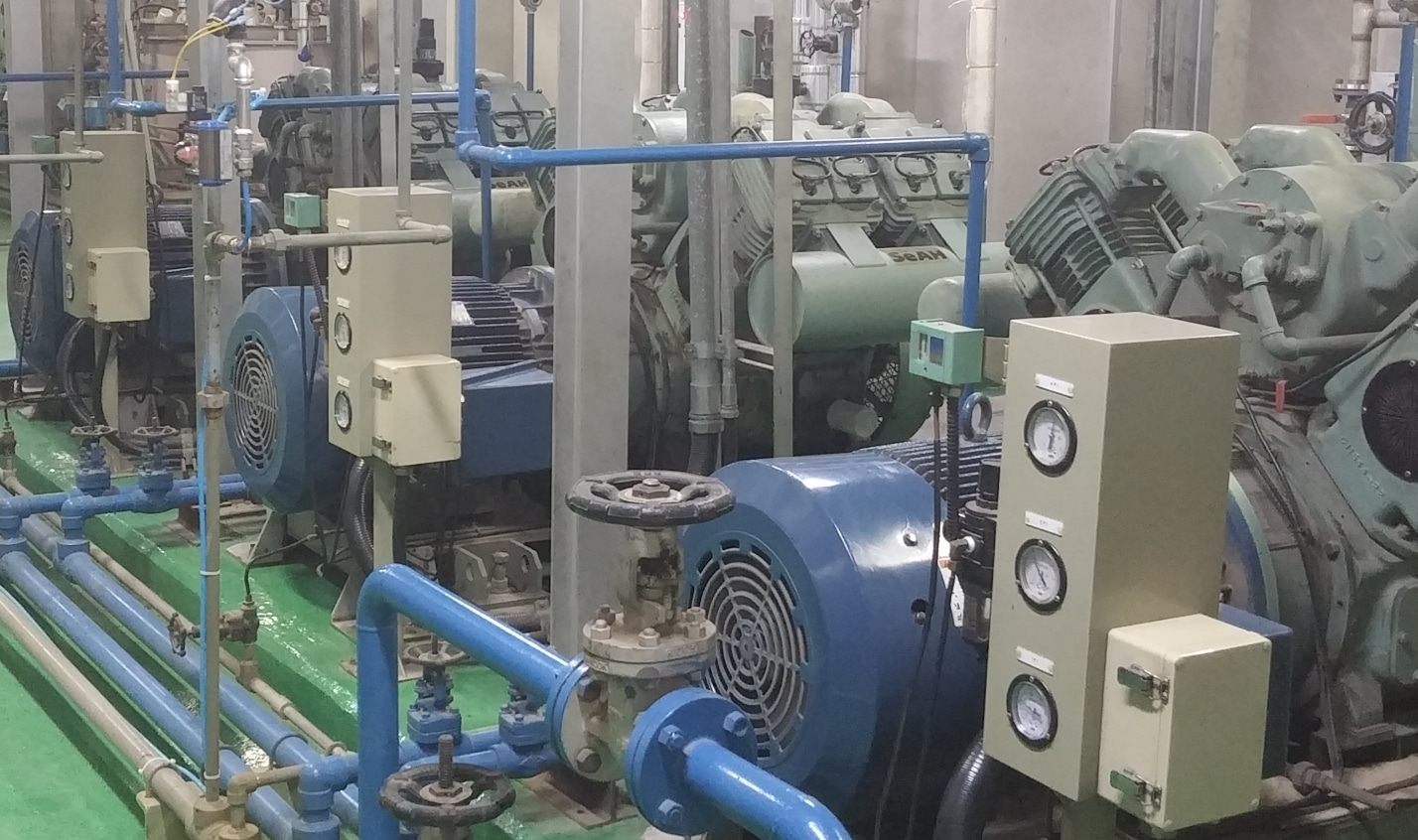

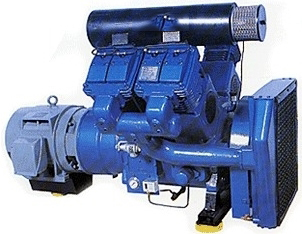

V-Series Piston Compressor

V-Series Piston Compressor

SEAH INDUSRTRY

V-package type of reciprocating compressor was utilized by COMPAIR BROOM WADE Co. in England and then, got a great reputations to the word-wide especially for its durability and reliability.

These kinds of V-series compressor have been manufactured and supplied for last 50 years by SEAH INDUSTRY and they got a good reputations from our customers.

|

|

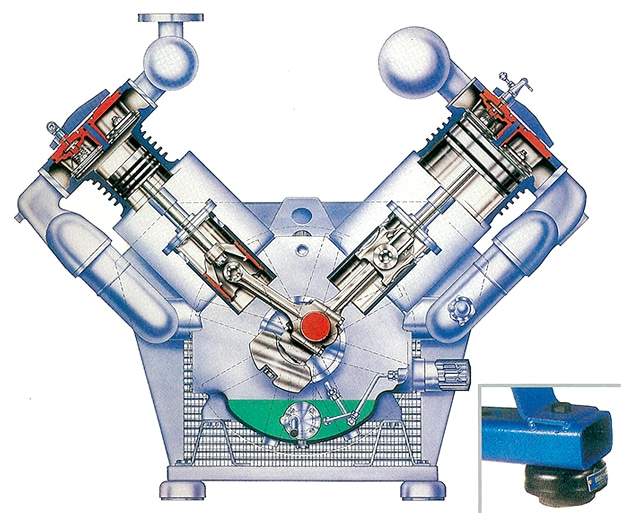

- Where production reliability is a prerequisite for industries demanding 100 % oil free air the V-series oil free compressor

is the answer. This includes the food, pharmaceutical and electronic industries and those using air for oil for

instrumentation or control purposes.

- V-series oil free comperssor incorporate carbonfilled PTFE( polytetrafluorethylene ) rings, which elimminate the need

for oil for cylinder lubrication.

- A distance piece incorporating 2 sealing glands is fitted between each cylinder and the crankcase, which insures that

the section of the piston rod entering the cylinder does not enter the crankcase. These measures gurantee the genuine

oil free operation of V-series.

- The compact design and low weight of the components along with maximum accessibility for service, ensure the

minimum downtime for annual overhaul and routine maintenance.

- By adopting two(2) stage compresson method which contribute to the excellent energy saving and

efficiency of compression.

- V-series is optional with air cooled and water cooled type to meet various requirement of customers.

|

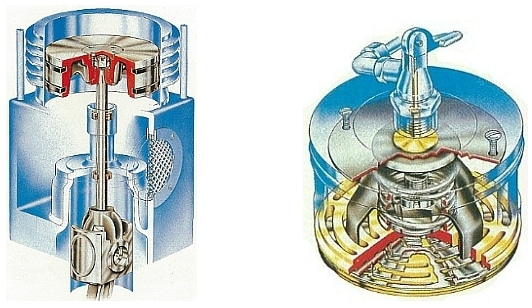

Valves Reduced maintenance and energy costs are major benifits of the frictionless. low lift, large flow area valves. oil free compressor valves are of a similar high specification. Moreover the whole valve assembly is coated with a rust resistant material to prevent corrosion caused by condensation, therby ensuring long, reliable life. |

|

Intake filter & silencer Replacement and maintenance costs are reduced by provision of a precision are filter and turned absorption silencer, noise levels are also considerably reduced. |

|

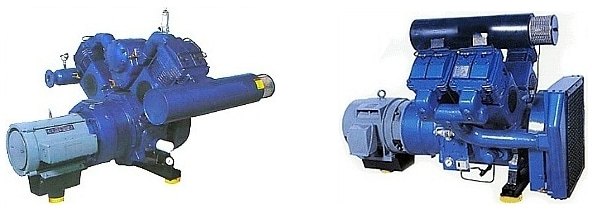

Bell housing

V-series compressors are so versatile they can be adapted to meet almost any markrt condions. in standard form the V-series compressor is driven by bell housing. Because driving equipment such as Motor bed, Cover and Belt etc. is not needed, maintenance and management as well as cost saving is convenient.

|

|

Vibration absorbing Pad

Simple, low cost installation is achieved by the balanced vee cofiguration linked with the vibration absorbing mounts. As no special foundations are required,the unit can be installed directly on any suitable subfloor, which allows a great variety of possible locations. |

Model |

V 20 DN/DH |

V 25 DS |

V30 DN/DH |

V 30 DS |

V 40 DN/DH |

V 40 DS |

V 50 DN/DH |

V 60 DN/DH | |

Motor |

kw |

15 |

18.7 |

22 |

22 |

30 |

30 |

37.5 / 37.3 |

45 |

Working pressure |

kg/cm2 |

7.0 / 8.5 |

10.5 |

7.0 / 8.5 |

10.5 |

7.0 / 8.5 |

10.5 |

7.0 / 8.5 |

7.0 / 8.5 |

Free air delivery |

m3/min |

2.26 / 2.24 |

4.60 |

3.37 / 3.34 |

3.0 |

4.62 / 4.56 |

4.50 |

5.91 / 5.80 |

6.90 / 6.84 |

Cylinder size(1st) |

inch |

7- 3/4 |

7- 3/4 |

8- 3/4 |

8- 3/4 |

7- 3/4 |

7- 3/4 |

8- 3/4 |

8- 3/4 |

Cylinder size(2nd) |

inch |

4- 1/2 |

4- 1/2 |

5- 1/4 |

5- 1/4 |

4- 1/2 |

4- 1/2 |

5- 1/4 |

5- 1/4 |

Stroke |

inch |

3- 3/8 |

3- 3/8 |

3- 7/8 |

3- 7/8 |

3- 3/8 |

3- 3/8 |

3- 3/8 |

3- 7/8 |

C/pipe dia.(air/out) |

inch |

2 |

2 |

2 |

2 |

2- 1/2 |

2- 1/2 |

2- 1/2 |

2- 1/2 |

C/pipe dia.(water/in) |

inch |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 3/4 |

PT 3/4 |

PT 3/4 |

PT 3/4 |

C/pipe dia.(water/out) |

inch |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 1/2 |

PT 3/4 |

C/water requirement |

L/min |

18 |

20 |

22 / 25 |

28 |

30 / 35 |

40 |

20.8 |

24.7 |

Out-line dimension ( mm ) |

Length |

1,640 |

1,640 |

1,715 |

1,715 |

2,108 |

2,108 |

2,108 |

2,108 |

Width |

1,100 |

1,100 |

1,460 |

1,460 |

1,100 |

1,100 |

1,200 |

1,200 | |

Height |

1,000 |

1,000 |

1,220 |

1,220 |

1,200 |

1,200 |

1,400 |

1,400 | |

Approx. weight |

kg |

740 |

740 |

850 |

850 |

1,100 |

1,100 |

1,300 |

1,420 |

※ V-series is driven by direct coupling ( bell housing )

※ Sarting method is star-delta type

※ "C/pipe dia." is the diameter of connection pipe

※ "C/water" is the cooling water, and ΔT of cooling water is 5℃.

※ Be careful that above specification can be changeable at any time without any prior notice

in order to to upgrade the quality and performance of the products.

-6.jpg)

-7.jpg)

-1.jpg)