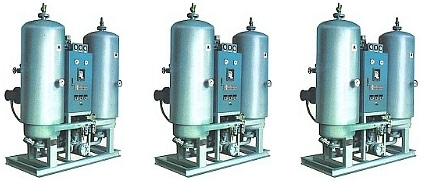

Desiccant Air Dryer (External Heater)

Desiccant Air Dryer

SEAH INDUSRTRY

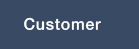

External Heater Type

-1.jpg)

- External heater type desiccant Air dryer

It is the desiccant equipment to fill high alumina gel having mositure and chemical attraction into the

tank in order to supply the pressure air of saturation come from air compressor under high dry status,

A typical regenerative dryer consists of two towers charged with activated alumina desiccant.

One tower dries air, while the desiccant in the other toweed with low pressure and low pressure

and low humidity air.

Often ,heat is added to assist the regeneration process. In this design, a small amount of the dried

air (from the drying tower) is expanded to near atmospheric pressure in the regenerating tower.

The dry air becomes super dry on expansion, and readily absorbs the moisture from the saturated

desiccant bed.

Like this, the machinery to reiterate the dehumidification and regeneration under allowed time

and then, supply the dried air is called as " Desiccant air dryer ".

Among them, in order to regenerate the desiccant, the dryer to install the electronic heater to

external tank and dry the absorbent is called as " External heater type desiccant air dryer ".

-2.jpg)

- As there is no touch on heater etc on the absorbent of inner tank, the life of theabsorbent gets longer.

- Outisde size is compact due to no driving equipments.

- It is directly connected with cooling air dryer and it is the best dryer tyle when utilizing.

- The life of heater was greatly increased by utilizing low density heater.

- The long maintenance free was realized by the reliable valve system and welding pipe.

-4.jpg)

|

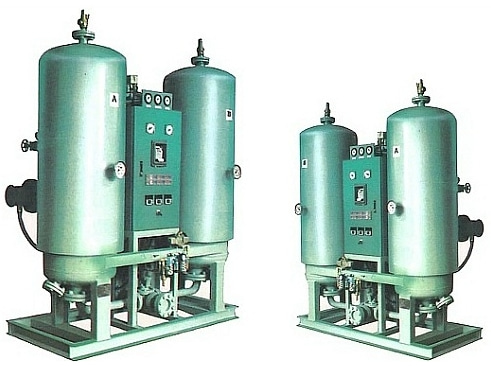

Model |

Capacity |

in/out |

Gel |

Heater |

Dimension ( mm ) |

Weight | |||

|

Nm3/min |

inch |

(A) |

kg/tower |

kw |

Width |

Depth |

Height |

kg | |

|

SHE 100 |

2.5 |

1 |

25 |

40 |

2.7 |

880 |

880 |

2,350 |

350 |

|

SHE 150 |

4.2 |

1-1/2 |

40 |

67 |

3.0 |

980 |

980 |

2,350 |

450 |

|

SHE 200 |

6.2 |

1-1/2 |

40 |

98 |

4.0 |

1,080 |

1,050 |

2,400 |

620 |

|

SHE 285 |

8.3 |

1-1/2 |

40 |

130 |

6.0 |

1,100 |

1,080 |

2,400 |

750 |

|

SHE 350 |

11.0 |

2 |

50 |

174 |

8.0 |

1,150 |

1,150 |

2,430 |

950 |

|

SHE 430 |

14.5 |

2 |

50 |

230 |

11.5 |

1,200 |

1,200 |

2,450 |

1,100 |

|

SHE 560 |

17.5 |

2-1/2 |

65 |

277 |

13.8 |

1,400 |

1,270 |

2,450 |

1,300 |

|

SHE 720 |

23.0 |

2-1/2 |

65 |

365 |

18.0 |

1,500 |

1,300 |

2,500 |

1,500 |

|

SHE 900 |

28.0 |

3 |

80 |

444 |

22.0 |

1,900 |

1,500 |

2,500 |

1,800 |

|

SHE 1100 |

32.5 |

3 |

80 |

515 |

25.0 |

2,000 |

1,600 |

2,550 |

2,200 |

|

SHE 1350 |

38.0 |

3 |

80 |

603 |

30.0 |

2,000 |

1,700 |

2,550 |

2,600 |

|

SHE 1550 |

49.2 |

4 |

100 |

781 |

38.0 |

2,200 |

2,000 |

2,650 |

3,000 |

|

SHE 2100 |

61.7 |

4 |

100 |

977 |

48.0 |

2,500 |

2,000 |

2,650 |

4,200 |

|

SHE 3000 |

90.0 |

6 |

150 |

1,428 |

60.0 |

2,800 |

2,100 |

2,700 |

5,200 |

|

SHE 4100 |

110.0 |

6 |

150 |

1,764 |

82.0 |

2,990 |

2,200 |

2,700 |

6,000 |

|

SHE 5400 |

158.3 |

6 |

150 |

2,240 |

108.0 |

3,300 |

2,300 |

2,700 |

6,800 |

|

SHE 6000 |

175.0 |

8 |

200 |

2,780 |

120.0 |

4,000 |

3,500 |

3,000 |

7,500 |

|

SHE 7000 |

200.0 |

8 |

200 |

3,170 |

140.0 |

4,400 |

4,000 |

3,000 |

9,000 |

|

SHE 9000 |

250.0 |

10 |

250 |

4,100 |

180.0 |

4,600 |

4,600 |

3,000 |

10,000 |

※ Capacity based on inlet temperature 38 ℃ , working pressure 7kgf/cm2G , dew point -40 ℃.

※ Standard desciccant is the activated alumina gel.

※ Heat exchanger equipped with dryer more than "SHE 430" is test acquired by

KOSHA ( Korea Occupational Safety and Health Agency )

※ Be careful that above specification can be changeable at any time without any prior notice

in order to to upgrade the quality and performance of the products.