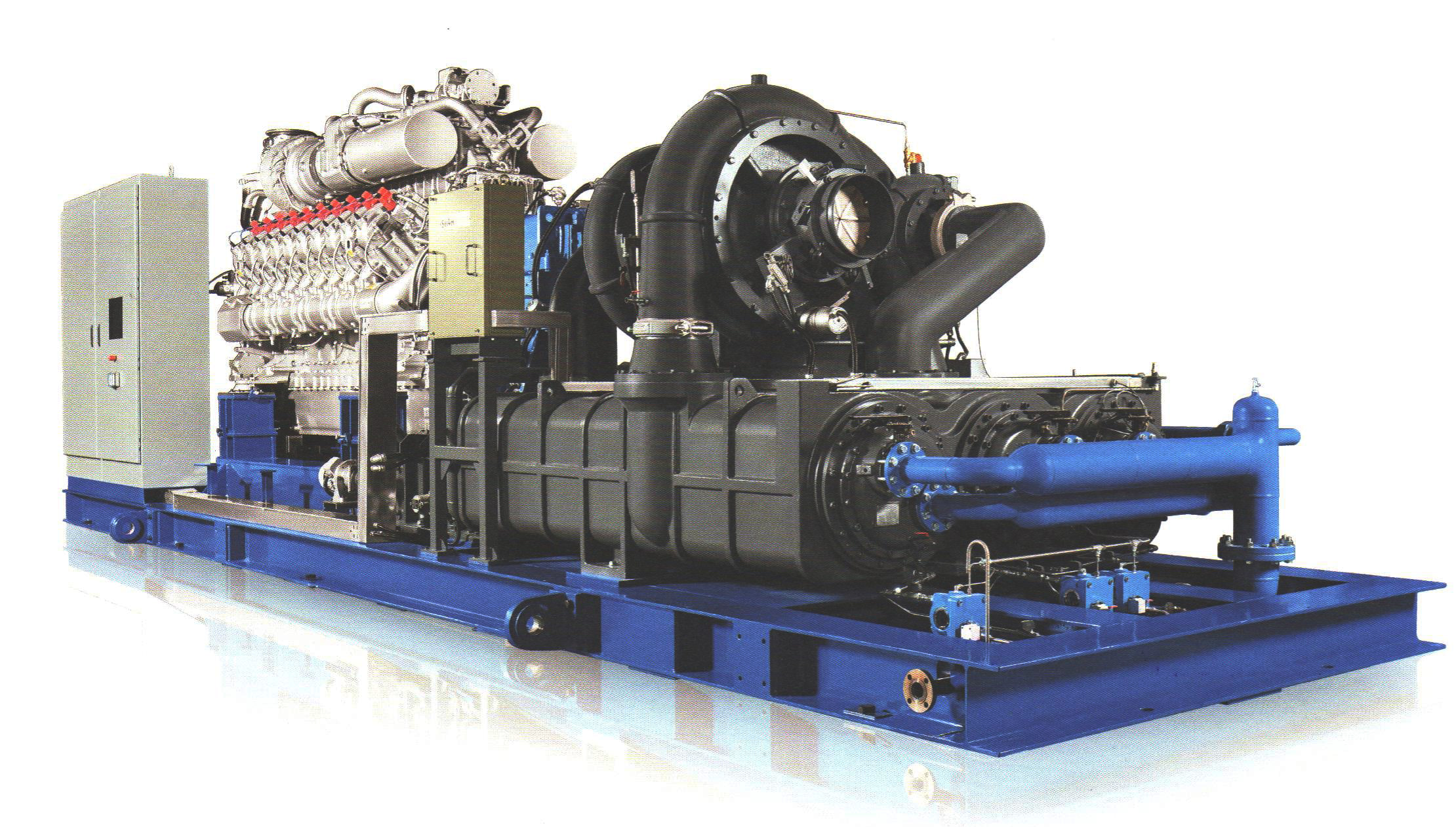

CHORUS Turbo compressor

CHORUS Turbo Compressor

SEAH INDUSRTRY

Innovative performance & Design

Innovative performance & Design

. Featuring inter & after cooler and Lub.oil system structrally separated from

compressor core unit ;

- Simple and compact design and noise minimized operation by adopting sound enclosure(option)

. Featuring 100% oil free and contamination free compressed air, it also provides ;

- Complete structural separation between lubricating and air compressing parts

. Maximum efficiency and quality safety are achieved by ;

- High efficiency design based on state-of-the-art computer simulation methods

- Adoption of the best quality components

- Reliability verification by 115% over speed spin test

. Plug & provides economic and Quick installation

- By immediately available single packaging design integrated after cooler

Easy Maintenance

Easy Maintenance

- By adopting horizontal split type gear cases, bearings, and air & oil seals

- Conventenance by adopting straght type water in tube bundles for inter & aftercooler

- Innovatively reduced hours of maintenance by module type design applied for all major components

Indefinite Durability

Indefinite Durability

- By Implementing strict quality control and test for all the main components

- Achieving impeccable durability and stability by established strict quality assurance system

for compression capability essential for stable operation

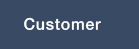

Optimal components High efficiency impellers Suction control device ( I.G.V ) Vibration monitoring system for each stage Horizontal split type gear case High efficiency main motor Lube system conforming to API 614 Surge control protection Modulating control PLC control panel (9.7" Touch screen) |

|

|

|

Application Process compressor Instrument compressor ASU Booster compressor Vacum compressor One or multi stage compressor |

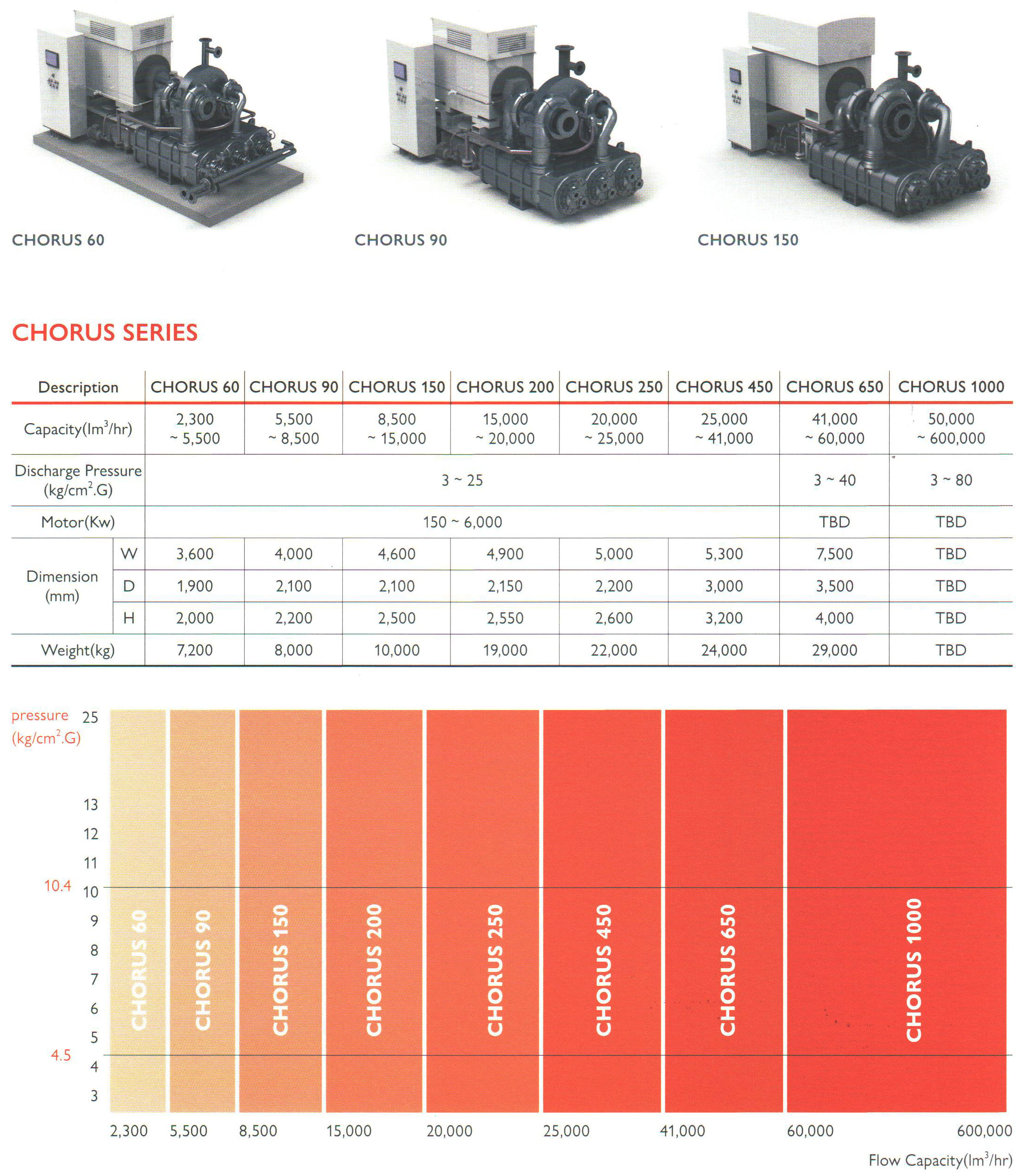

Model line-up & Specification

Model line-up & Specification

※ Be careful that above specification can be changeable at any time without any prior notice

in order to to upgrade the quality and performance of the products.

Description | CHORUS 30 | CHORUS 60 | CHORUS 90 | CHORUS 150 | CHORUS 200 | CHORUS 250 | CHORUS 450 | CHORUS 650 | CHORUS 1000 | |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity(㎡/hr) | 2,100~2,450 | 2,450~5,500 | 5,500~8,500 | 8,500~15,000 | 15,000~20,000 | 20,000~25,000 | 25,000~41,000 | 41,000~60,000 | 50,000~600,000 | |

Discharge Pressure (kgf/㎠G) | 2~8 | 3~25 | 3~40 | 3~80 | ||||||

Motor (Kw) | 140~260 | 150~6,000 | TBD | TBD | ||||||

Dimension (mm) | W | 2,650 | 3,600 | 4,000 | 4,600 | 4,900 | 5,000 | 5,300 | 7,500 | TBD |

D | 1,550 | 1,900 | 2,100 | 2,100 | 2,150 | 2,200 | 3,000 | 3,500 | TBD | |

H | 1,650 | 2,000 | 2,200 | 2,500 | 2,550 | 2,600 | 3,200 | 4,000 | TBD | |

Weight (Kg) | 5,900 | 7,200 | 8,000 | 10,000 | 19,000 | 22,000 | 24,000 | 29,000 | TBD | |

The principle of compressed air for turbo compressor

The principle of compressed air for turbo compressor

During the air compression, inlet air from inlet port is filtered through suction filter, the suction rate of air is

controlled by I.G.V(inlet guide vane) and then, it is supplied into first stage compression part.

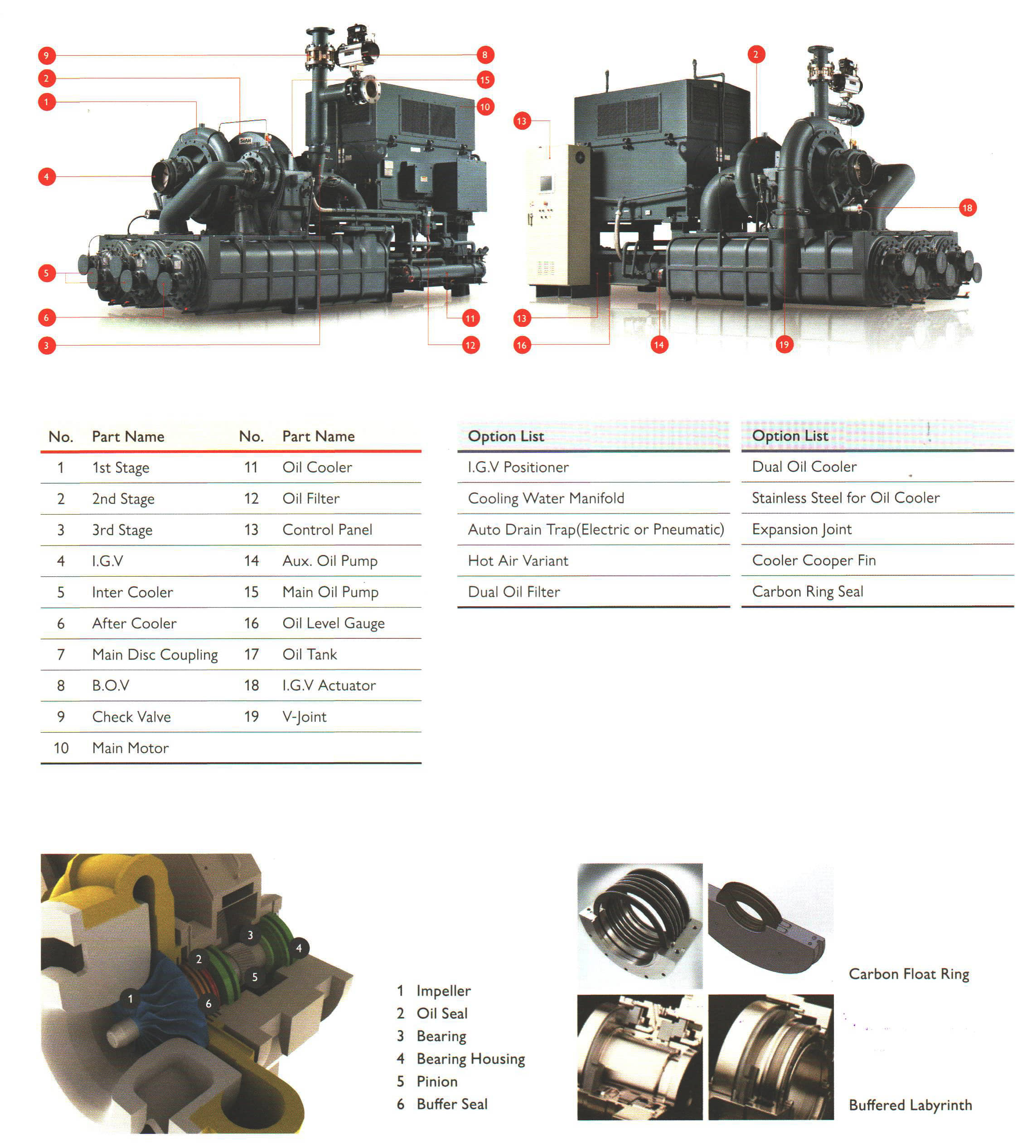

The principle of compressed air is that the centrifugal force to rotate impeller at high speed accelerates the air

and then, fixed diffuser is changed to pressure.

The R.P.M(revolutions per minute) of impeller is greatly increased by utilizing the difference of gear ratio between

bull gear and pinion gear of the R.P.M of main motor.

Compressed air to be increased to about 2 bar at 1st stage is cooled through inter cooler at first stage and then,

is supplied into compression part at second stage.

Cooled air is compressed by second impeller, rotating same speed as first impeller and then, is cooled after

supplied into second inter cooler.

Compressed air to be supplied into third stage compression part is compressed again by impeller and is reached

to optimal design condition through after cooler.

Compressed air to be reached to the finally required pressure condition is supplied into each air receiver tank

through D.C.V(discharge check valve) in order to protect the reversal of compressed air in the turbo compressor.