Current Page

After cooler (Water Cooled)

After Cooler

SEAH INDUSRTRY

Water Cooled Type

-1.jpg)

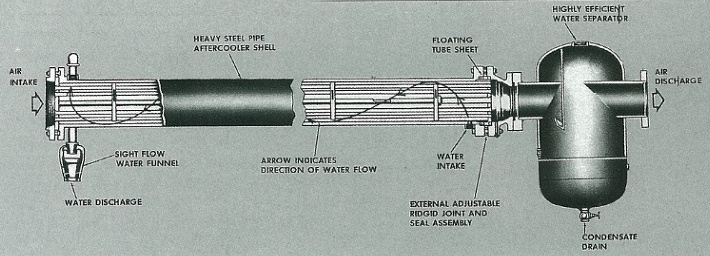

It is well known that hot and moisturized air coming from an air compressor usually causes malfunction

and damage to application equipment, disrupting production and affecting quality.

After cooler is essential cooling assist device to cool high tempeture and humid compressor air firstly

and then, stabilize the compresser air into free air tempeture status.

After cooler of water cooling tyle provided by SeAH is "Tube & shell type" and can get the best cooling

efficiency because water pass on the sheel and air pass on the tube. Futhermore, moisture separator tank

is equipped with standard status and it plays a role to safe pulsation at the course of compressure as

well as moisture separation of compressed air.

-2.jpg)

* High cooling efficiency is guaranteed as cooling system utilizing the water compared with air cooling system

* As shell & tube type, life is long and the decomposition on repairing and maintenance is easy.

* Because moisture separator tank is equipped in standard status, water separation is maximized

and pulsation is stabilized.

* After long utilizing, high cooing efficiency like first time can be kept by exchanging tube nest only.

.

-3.jpg)

Model |

Capacity (m2/min) |

Connection pipe diameter (in/out) |

Cooling - surface |

Approx. Weight | ||

1 stage |

2 stage |

Air |

Water |

m2 |

kg | |

PB 0 |

2.6 |

3.4 |

3 B |

3/4 B |

0.93 |

185 |

PB 0.5 |

3.3 |

4.2 |

3 B |

3/4 B |

1.05 |

194 |

PB 1 |

4.2 |

5.4 |

3 B |

3/4 B |

1.30 |

203 |

PB 1.5 |

6.8 |

8.4 |

4 B |

3/4 B |

1.54 |

232 |

PB 2 |

10.0 |

11.6 |

4 B |

3/4 B |

2.35 |

236 |

PB 2.5 |

12.0 |

14.8 |

6 B |

1-1/4 B |

3.08 |

324 |

PB 3 |

14.2 |

17.0 |

6 B |

1-1/4 B |

3.57 |

331 |

PB 4 |

16.7 |

20.2 |

6 B |

1-1/4 B |

4.23 |

342 |

PB 4.5 |

19.0 |

23.8 |

6 B |

1-1/4 B |

4.79 |

353 |

PB 5 |

21.9 |

26.4 |

6 B |

1-1/4 B |

5.52 |

360 |

PB 6 |

25.5 |

30.6 |

6 B |

1-1/4 B |

6.41 |

371 |

PB 7 |

35.4 |

42.6 |

8 B |

1-1/4 B |

8.92 |

455 |

PB 7.5 |

43.4 |

52.4 |

8 B |

1-1/4 B |

10.94 |

484 |

PB 8 |

46.0 |

57.0 |

8 B |

1-1/4 B |

11.60 |

490 |

PB 9 |

58.6 |

70.5 |

10 B |

1-1/2 B |

14.70 |

540 |

PB 9.5 |

68.0 |

79.6 |

10 B |

1-1/2 B |

16.66 |

567 |

PB 10 |

75.3 |

90.6 |

10 B |

1-1/2 B |

18.90 |

576 |

※ Max. working pressure : 9.9 kg/cm2 G

※ Hydraulic pressure test : 15.7 kg/cm2 G

※ Material of tube is the Copper.

※ Be careful that above specification can be changeable at any time without any prior notice

in order to to upgrade the quality and performance of the products.