Compressor is the machine to elevate air-pressure up to the designated / required level by compressing

the inhaled air at atmosphere by power.

1. Type and classification of air-compressor

A ) Classification by air-compressing methods

* Reciprocating or Piston type : Air-compressing by reciprocating piston.

* Rotary screw type : Air-compressing by screwing male & female rotor.

* Centrifugal or Turbo type : Air-compressing by impeller’s centrifugal force of ultra-high speed rotation.

B ) Classification by possession of lubricant / Injected oil

* Oil Injected or Oil flooded type : Air-compressing type to provide oil in compressing process in order to lubricate and seal,

which contain oil and price is relatively low compared with Oil free type.

* Oil Free or Non lubricated type : Air-compressing type without providing oil in compressing process, which does not contain

oil in compressed air, but would be expensive by special mechanism and materials.

C ) Classification by cooling methods of air-compressing

* Air cooled type : High temperature during compression is incurred and therefore any media to any media to cool

it is needed, For which air is utilized.

* Water cooled type : Water as cooling media is utilized. Its efficiency is good, but other mechanical

equipment is additionally needed and its price is expensive.

D ) Classification by air-compressure rate

A Compressor can raise the pressure of air to high level and generally 6~8Kg/㎠g is classified as normal level

and therefore, If it is less than this level, It can be classified as low pressure, while high, as high pressure. meantime,

If it is higher than 15Kg/㎠g , it can be classified as super high pressure.

E ) Classification by the capacity of compressed air

Generally it is indicated as horse power(Hp), the capacity of electric motor. If it is less than 10 Hp, it can be classified as

small type, 10~250 Hp is middle Type, 260~900 Hp is large type and more than it, as super large type.

F ) Portable type and Stationary type

There are two(2) types, that is, Portable type can be movable, but Stationary type is utilized as fixed status in

the certain place. Normally in case of stationary type, electric motor is utilized, while in case of movable,

generator to generate electric power itself should be equipped.

2. Accessories of air-compressor

A ) Cooler

High temperature in the processing of making compressed air is included and compressure air can be

utilized by cooling it, for which separate equipment is cooler (Air cooled and Water cooled).

B ) Dryer

A lot of moisture including in the atmosphere in the condensed air is also compressed and therefore,

the equipment to get it is Air Dryer.

* The type of dryer

I) Desiccant type : An Desiccant to dry it is utilized such as silica gel or activated alumina

and its price is relatively high compared with Refrigerated type.

II) Refrigerated type : The compressed air to cool it is utilized and it can be dried as heat exchange type

and price is relatively low compared with desiccant type.

C ) Receiver tank

The compressed air contains high pressure and therefore, this is the equipment to store in the vessel and then,

utilized it in case of necessity.

* At present KOSHA ( Korea Occupational Safety and Health Agency ) issues examination certificate

after inspecting all matters from design to its performance.

D ) Filter

Many other matters including moisture and dust etc can be contained in the compressed air and therefore,

many kinds of filters are utilized in order to remove them.

-1_00000.jpg)

3. Basic lay-out for compressor with Accessories

A : General industrial use.

B : Measuring equipments, Electrostatic painting, precision process,Textile manufacturing, Ordinary electronics Industries.

C : Medicine, Oxygen & Ozone & Nitrogen Production apparatus, Semiconductor, Supreme precision, Powder Coating,

Bio chemical, Nano technology, Chemical process.

-2.jpg)

4. The use of compressed air

Compressed air has high temperature and it can be utilized as the way to transfer the power

and or increase the certain measurement and or increase the speed by taking advantage of this pressure.

A ) Living surroundings

- Pumping air into the tire

- Pneumatic tools

- Spray guns for Painting work.

- Cleaning purposes at industrial site .

- Golf shoes cleaning.

- Dental treatment.

- Breathing apparatus for divers & Miners.

B ) Industrial site

- Machinery and equipment are operated by utilizing Air cylinder

- To turn on/off the valve auotmatically

- When spinning as air jet loom

- Glass forming process.

- Tablet making process

- Air hammer for steel forging.

- Compressed airs are utilized on all kinds of machinery and equipment.

* Generally all factories require compressed air together electric power.

C ) These compressors are required on all industrial sites and Large or Super size compressor are mostly utilized on

Power plant, Incinerator, Shipbuilding, Steel industry, Glass & Textiles, Car & Robot industry, Electrical & Electronics,

Semiconductor industry, Dye works, Petrochemical plant, Bio chemical, Nano technology, Food & Beverages,

Pharmaceutical industry, Paper & pulp, District heating Plant etc.

5. Gas Compressor

Beforehand air compressure to condense air in the atmosphere was mentioned. However, If the fluid

for compressure is not air but gas, they can be Nitrogen compressor, Oxygen compressor, Argon compressor,

LNG compressor, LFG compressor, Natural gas compressor, Steam compressor according to its kind of gas.

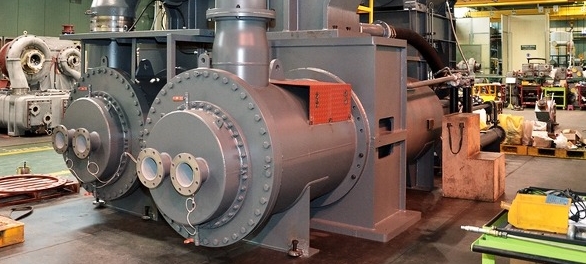

6. Product range of SeAH's compressor

- Turbo ( Oil free ) : Air, Gas, Steam Compressor ( 350~6,000 Hp )

- Piston ( Oil free ) : Air, Gas Compressor ( 20~900 Hp )

- Screw ( Oil flooded , Oil free ) : Air Compressor ( 10~500 Hp )

7. SeAH Supplies the complete compressed air & gas system

-1.jpg)

-1.jpg)

Comments can be added by Member only.